Ever pulled a vibrant photo out of your printer and marveled at how a machine can seemingly just create such a detailed image? It feels like magic, but the reality is even more fascinating. It’s a symphony of incredible precision and microscopic engineering happening right under your nose.

At the heart of it all is the inkjet printer’s print head, a marvel housing thousands upon thousands of microscopic nozzles. We’re not talking small; we’re talking apertures tinier than a single strand of human hair. Through these minuscule openings, the printer propels droplets of ink so astonishingly small – measured in pico-liters (trillionths of a liter!) – and at speeds faster than you can even register. It’s this controlled ejection of pico-sized ink particles that forms the foundation of every image.

Table of Contents

The Core Players: CMYK Ink

Inkjet printers primarily use just four ink colors: Cyan (a blue-green), Magenta (a purplish-red), Yellow, and Black (often referred to as Key, hence CMYK). While this might seem limiting, the magic happens when these four colors are combined and layered in varying densities. By strategically placing and overlapping these four basic inks, the printer can simulate millions of different hues and shades needed to reproduce a full-color photograph or graphic. Think of it like building a grand mosaic, except your tiles are invisible specks of ink, layered to create the illusion of continuous tone and color.

There are two main types of ink commonly used:

- Dye-based inks: These are made of colorants dissolved in a liquid. They are typically more vibrant and produce smoother gradations, making them excellent for printing photos. However, they can be less resistant to fading and water compared to pigment inks.

- Pigment-based inks: These inks contain solid color particles suspended in a liquid. Pigment inks offer superior longevity, water resistance, and UV resistance, making them ideal for printing documents and images that need to last. They tend to produce sharper text as well.

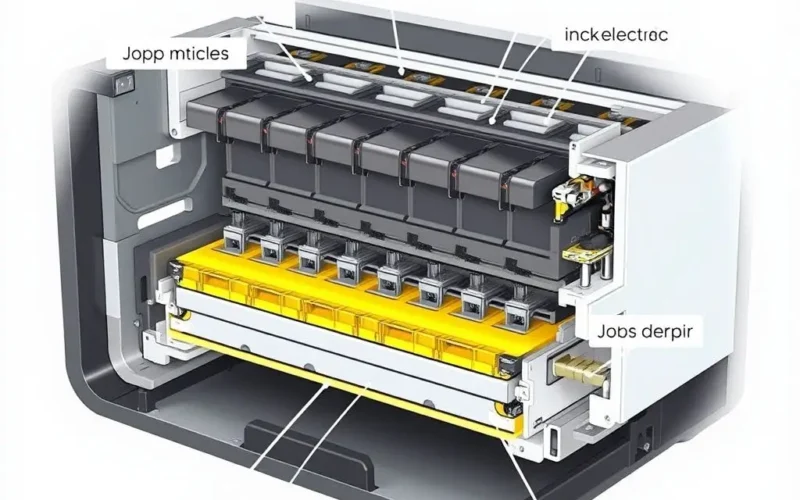

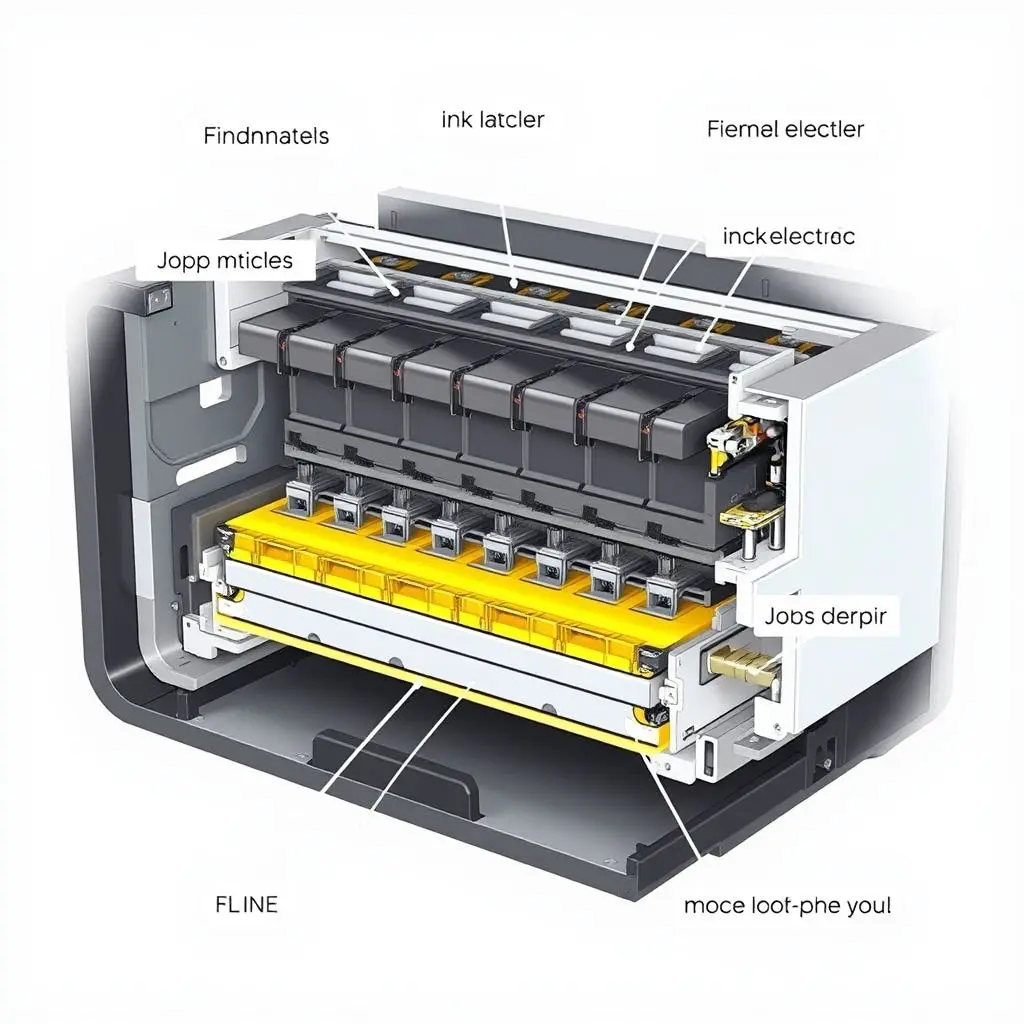

The Ingenious Print Head: Ejecting the Tiny Drops

The print head is arguably the most complex part of an inkjet printer. It’s the component that physically delivers the ink onto the paper. Inside, the ink from the cartridges flows into reservoirs connected to the array of nozzles. But how does the ink get from the nozzle to the page?

There are two primary technologies for ink ejection:

- Thermal Inkjet: Used by brands like HP and Canon. In this method, tiny resistors located at the back of the nozzles heat the ink rapidly, creating a small steam bubble. This bubble expands, pushing a droplet of ink out through the nozzle onto the paper. The bubble then collapses, and surface tension pulls more ink into the chamber, ready for the next firing cycle. This process happens thousands of times per second for each nozzle.

- Piezoelectric Inkjet: Used by brands like Epson and Brother. This technology uses piezoelectric crystals positioned at the back of each nozzle. When an electric current is applied, the crystal changes shape, flexing inwards. This sudden movement displaces a tiny amount of ink, forcing a droplet out of the nozzle. When the voltage is removed, the crystal returns to its original shape, drawing more ink into the chamber. This method allows for more control over droplet size and speed.

Regardless of the method, the precision required is astounding. The printer’s controller board tells each individual nozzle exactly when and how to fire, orchestrating a complex dance of ink ejection as the print head rapidly sweeps across the paper.

From Drops to Dots: Building the Image

The fired ink droplets land on the paper, forming tiny dots. The perceived sharpness and detail of a printed image depend heavily on how many dots can be placed within a given area, a measurement known as Dots Per Inch (DPI). Higher DPI means more dots per inch, leading to finer detail and smoother transitions.

But placing dots is just one part of the equation. To create the illusion of continuous tones and millions of colors from only four inks, inkjet printers use techniques like:

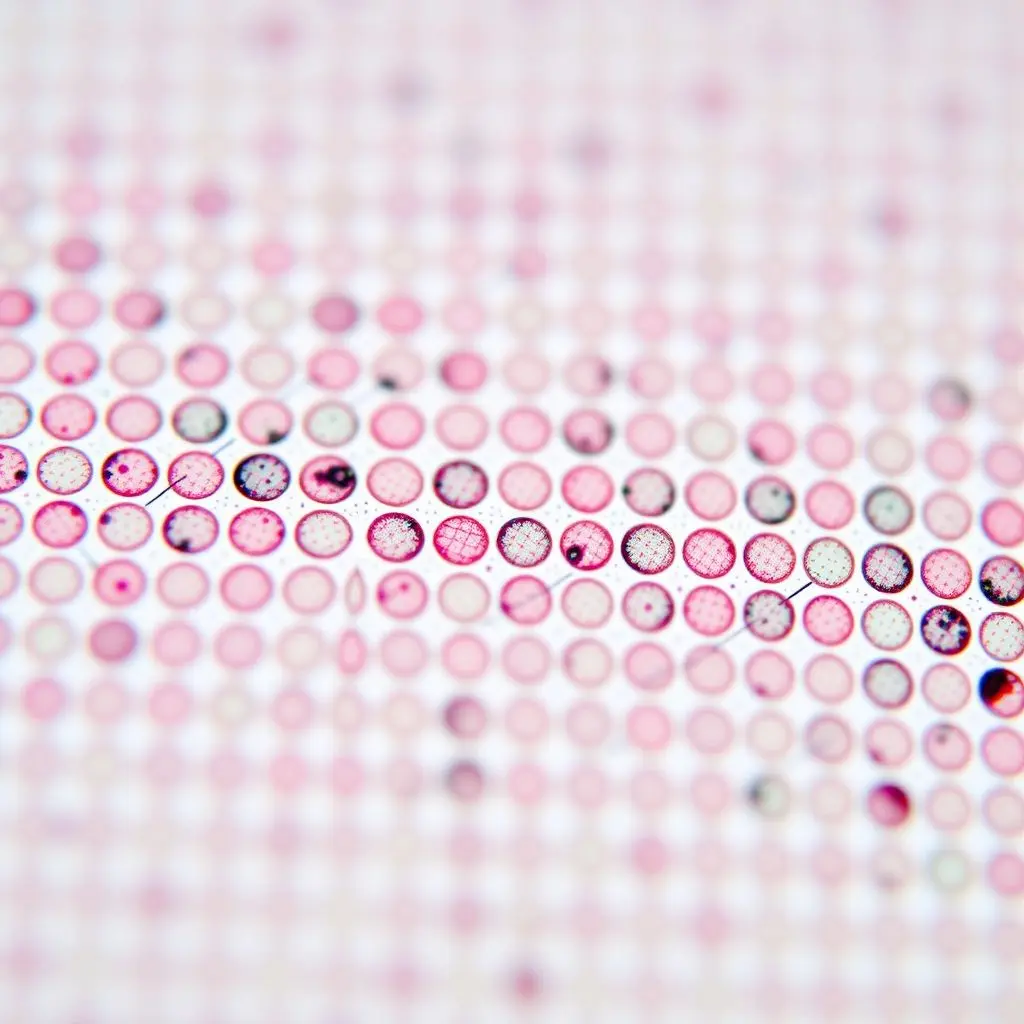

- Halftoning: This is a technique where the perceived shade or color is created by varying the density and pattern of dots of a limited number of colors. Look closely at a newspaper photo or an older printed image, and you might see patterns of dots. The human eye blends these dots together from a distance, perceiving them as continuous tones.

- Dithering: Similar to halftoning, dithering uses different patterns of dots to simulate colors or shades that are not available in the basic ink set, often adding a small amount of noise or randomness to the dot placement to reduce banding and create smoother transitions.

By precisely controlling the size (in some piezoelectric systems) and placement of these incredibly small CMYK dots, and layering them on top of each other or side-by-side, the printer builds up the complex interplay of color and light that forms the final image.

The Paper’s Journey

While the print head is busy ejecting ink, the printer’s paper handling mechanism ensures the paper moves through precisely, one line at a time, allowing the print head to deposit ink in the correct location. Rollers and motors work together to feed the paper, pause it, and advance it as needed, all synchronized with the rapid firing of the nozzles.

Keeping the Magic Alive: Maintenance

Given the microscopic nature of the nozzles and ink, maintenance is crucial. Inkjet printers regularly perform cleaning cycles. These cycles purge a small amount of ink through the nozzles to prevent clogs caused by dried ink. While they consume ink, they are essential for maintaining print quality and preventing more serious issues down the line.

Want a super quick visual peek into this fascinating process? Check out this lightning-fast summary:

Going Deeper: Factors Influencing Print Quality

The quality of an inkjet print isn’t solely determined by the printer’s engine. Several factors play a significant role:

- Resolution (DPI): As mentioned, higher DPI generally means more detail. Printers offer various DPI settings, and choosing the right one depends on the output (text vs. photo) and desired quality.

- Ink Quality: Using high-quality, compatible ink is vital. Poor quality or incompatible inks can clog nozzles, produce inaccurate colors, and fade quickly. Genuine manufacturer inks are designed specifically for the printer’s print head technology and paper types.

- Paper Type: Different papers absorb ink differently. Glossy photo paper is treated to prevent ink from soaking in, allowing dots to remain sharp on the surface for vibrant colors and high detail. Standard copy paper is more absorbent, which can lead to dots spreading and a less sharp image. Choosing the right paper for your print task is crucial.

Frequently Asked Questions About Inkjet Printing

Still have questions about how this tiny-drop technology works?

Why do printers use CMYK instead of RGB?

RGB (Red, Green, Blue) is used for displaying colors on screens by adding light. CMYK is used for printing by subtracting light. Inkjet inks are pigments that absorb certain wavelengths of light and reflect others. By combining cyan, magenta, and yellow inks, they absorb different amounts of red, green, and blue light respectively, creating a wide spectrum of colors. Black ink adds density and contrast, especially for shadows and fine text, and is more economical than mixing CMY to create black.

Why are cleaning cycles necessary and do they waste ink?

Yes, cleaning cycles use a small amount of ink. However, they are crucial because the ink in the tiny nozzles can dry out and clog them, especially if the printer isn’t used regularly. Clogged nozzles result in missing lines, banding, and inaccurate colors in your prints. Regular cleaning prevents these issues, ultimately saving you frustration and potentially more ink than would be wasted on failed prints or professional cleaning.

Why do inkjet prints sometimes fade over time?

Fading is often due to exposure to UV light and environmental factors. The type of ink used plays a big role. Dye-based inks are more susceptible to fading than pigment-based inks. The quality of the paper also matters, as well as storage conditions (e.g., framed behind UV-protective glass). Using archival-quality pigment inks and acid-free paper can significantly increase the longevity of prints.

A Microscopic Marvel

So, the next time you admire a photo printed by an inkjet, remember the incredible precision behind it. It’s not just squirting ink; it’s thousands of microscopic nozzles, firing pico-liter droplets at lightning speed, combining just four colors to build intricate images dot by invisible dot. It’s a tiny, complex dance resulting in epic art. The technology we use every day truly is packed with miniature wonders!