Driving across a colossal suspension bridge feels a bit like magic, doesn’t it? You’re soaring hundreds of feet above water or land, held aloft by seemingly delicate strands stretching across vast distances. The sheer scale is breathtaking, and it’s only natural to wonder: how on earth does this massive structure defy gravity?

It might look like an impossible feat, but it’s not magic at all. It’s a stunning showcase of incredible engineering, materials science, and a clever dance between opposing forces happening right before your eyes. Think of the deck you drive on not as a support structure itself, but rather as something being carefully *hung* from above.

Table of Contents

Ever Wonder How Suspension Bridges Stay Up? Watch This Quick Clip!

Before we dive deep into the nuts and bolts, get a quick visual rundown of the fundamental concept in this short clip:

Pretty wild, right? It gives you a hint at the ingenious system at play. Let’s explore the components that make this engineering marvel possible.

The Core Concept: Hanging the Roadway

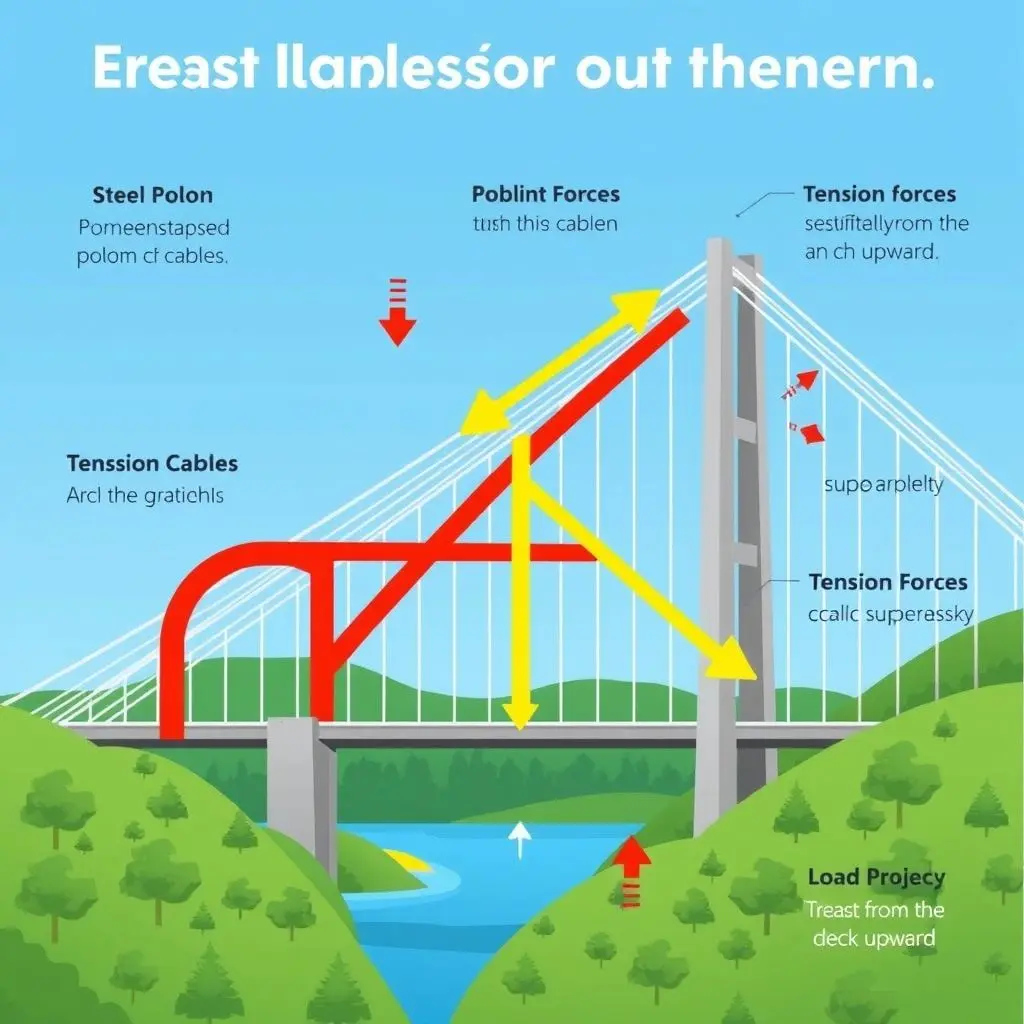

At its heart, a suspension bridge works on a simple, yet powerful principle: tension. Unlike beam or arch bridges that primarily rely on compression from below or beside to support the load, a suspension bridge supports its deck by hanging it from powerful cables stretched between towering supports. The weight of the bridge deck and everything on it (cars, trucks, wind forces) is transferred upwards through hangers to the main suspension cables.

The Giants That Bear the Load: Pylons

Standing tall as the most visible elements after the deck, the pylons (or towers) are the vertical sentinels of a suspension bridge. Their primary job is to support the massive main cables as they drape from one side to the other. The main cables exert an enormous downward force on the pylons, meaning the pylons are under immense compression. They are essentially pushing back against the incredible pull of the cables. Because they carry such a concentrated load and often stand in challenging environments (like deep water), their foundations must be incredibly robust, often anchored deep into bedrock.

The Heart of the Bridge: The Main Cables

These are the true lifelines of the suspension bridge, handling the lion’s share of the structural work. The main cables are under extraordinary tension – they are pulled taut between the anchorages, draped over the pylons. Each main cable isn’t a single solid piece; it’s spun or prefabricated from tens of thousands of individual, high-strength steel wires. Using many small wires instead of one large bar offers greater flexibility, redundancy (if one wire breaks, the cable as a whole remains strong), and allows for easier fabrication and handling. The sheer strength required means these wires are typically made from steel alloys capable of withstanding staggering amounts of pull force.

The Hidden Strength: Anchorages

Perhaps the most crucial, yet often unseen, components are the anchorages. Located at each end of the bridge, typically buried deep within the earth or integrated into massive concrete structures, the anchorages are the immovable objects that resist the gargantuan pull of the main cables. Remember how the cables are under immense tension? The anchorages are what hold that tension. They must be heavy and strong enough to withstand the full horizontal force of the main cables trying to pull them inwards. Some anchorages rely purely on their immense weight (gravity anchorages), while others are anchored into rock tunnels or reinforced concrete blocks deep underground. Their failure would be catastrophic, so they are engineered with huge safety margins.

Connecting the Dots: Suspenders and the Deck

Smaller vertical cables, known as hangers or suspenders, connect the bridge deck to the main suspension cables above. These suspenders transfer the weight of the deck and the traffic load directly upwards to the main cables. The deck itself, often reinforced with a stiffening truss or box girder structure, isn’t designed to carry the load over long spans like a traditional beam. Instead, its main function is to provide a level roadway and, crucially, to resist bending and twisting forces caused by wind and uneven traffic loads. Without the stiffening structure, the deck could undulate or twist violently, potentially leading to structural failure (as famously seen with the Tacoma Narrows Bridge disaster before modern design principles evolved).

The Ballet of Forces: Tension and Compression

The magic of a suspension bridge lies in this elegant system: The deck’s weight creates tension in the vertical suspenders. This tension is transferred to the main cables, putting them under massive tension. The main cables pull downwards on the pylons, putting the pylons under extreme compression. Finally, the tension in the main cables is resisted by the sheer mass and strength of the anchorages. It’s a beautiful, balanced system where forces are distributed and transferred, allowing for incredible span lengths unmatched by most other bridge types.

Built to Last (and Sway)

Modern suspension bridges are not rigid. They are designed with a degree of flexibility to withstand dynamic loads like wind gusts and the vibrations caused by traffic. This slight movement is normal and a sign that the bridge is dispersing forces as intended. Engineers use sophisticated computer modeling to understand and predict how a bridge will behave under various conditions, ensuring its safety and longevity.

Frequently Asked Questions About Suspension Bridge Tech

- How strong are the main cables? Incredibly strong. A single strand of wire used in these cables can often hold several tons. When thousands of these wires are bundled together, the resulting cable can support tens of thousands of tons.

- Why do suspension bridges sway? Slight swaying or vibration is normal and intentional. It allows the bridge to dissipate energy from wind, traffic, and even seismic activity, preventing damaging stress build-up.

- What are anchorages made of? Typically, massive blocks of concrete reinforced with steel. They are often embedded deep in the ground or rock formations to use the weight and strength of the earth itself to resist the cable tension.

- Can suspension bridges handle earthquakes? Modern suspension bridges are designed with seismic considerations in mind, using techniques like seismic isolators and dampeners to absorb ground motion and prevent structural damage.

Beyond the Structure: A Marvel of Human Ingenuity

Standing as testaments to human creativity and perseverance, suspension bridges are more than just crossings; they are symbols of connecting disparate places, overcoming geographical barriers, and pushing the limits of what’s possible. They are a fascinating blend of art, advanced materials, precise mathematics, and sophisticated understanding of physical forces, working in concert to create structures that inspire awe and facilitate commerce and travel on a grand scale.