Let’s talk about the real rockstars of the ancient world: the engineers! Forget the mystical theories for a moment and appreciate the sheer brainpower that went into creating structures that defy time. Look at a pyramid, stare up at a towering Roman aqueduct arch, and the inevitable question pops into your head: how?

It wasn’t merely boundless human labor. While brute strength played a part, it was the ingenious application of fundamental physics, geometry, and resourcefulness that truly built these marvels. We’re delving into civilizations that faced monumental challenges and engineered solutions that remain standing, a testament to their incredible technological prowess.

Curious to see some of these ideas brought to life visually? Check out this quick dive into the ancient tech mindset:

Alright, let’s dig deeper than a pharaoh’s tomb and explore the mechanics.

Table of Contents

The Pyramid Puzzle: Moving Mountains of Stone

The Great Pyramid of Giza alone is estimated to contain over 2.3 million stone blocks, some weighing upwards of 80 tons (that’s heavier than a modern battle tank!). Building such a structure over 4,500 years ago required solving complex problems:

Quarrying the Giants

Much of the stone, particularly the softer limestone for the core, was quarried locally. Harder granite, used for burial chambers and structural elements, came from Aswan, hundreds of miles away. How did they cut these massive blocks with only copper or bronze tools?

Evidence suggests techniques involved using stone or wooden mallets and copper chisels for softer stone. For harder granite, they likely employed dolerite pounding stones to break the rock and potentially used methods like drilling holes and inserting wooden wedges, which were then soaked with water. As the wood expanded, it would split the rock. Sand, used as an abrasive with saws, would have aided cutting.

Transporting the Immense Loads

Getting stone from the quarry to the pyramid site was a logistical feat. Local limestone might be moved relatively shorter distances, perhaps on sleds dragged over surfaces lubricated with water or mud, or possibly over carefully prepared causeways. For the granite from Aswan, river transport via barges during the Nile’s annual inundation would have been essential, bringing the stones closer to the Giza plateau.

Lifting and Placement: The Ramps Debate

This is perhaps the most debated aspect. How did they lift stones weighing tens of tons hundreds of feet into the air? The most widely accepted theories involve ramps. However, the type of ramp is still a hot topic among Egyptologists and engineers:

- Straight Ramp: A single ramp extending outwards. Requires an immense volume of material and becomes incredibly long at steeper angles needed to reach the top, making it impractical.

- Spiral Ramp: A ramp winding around the pyramid’s exterior. Possible, but would cover parts of the structure, making exterior finishing difficult during construction.

- Internal Ramp: A ramp winding upwards within the pyramid’s core. Recent research suggests this might be plausible for the upper levels, potentially explaining certain structural features observed via modern scanning techniques.

Regardless of the ramp type, moving stones up would likely have involved sleds, ropes, and large teams of workers. Simple machines like levers would have been crucial for positioning blocks precisely once they reached their destination height. Evidence of careful planning, leveling, and surveying is clear in the pyramid’s near-perfect cardinal orientation and incredibly close-fitting stones.

Roman Aqueducts: Masters of Flow and Form

While the Egyptians built upwards, the Romans conquered distance with water. Their aqueducts were not just channels; they were sophisticated gravity-driven systems designed to supply cities with clean water over many miles, sometimes across challenging terrain.

Surveying for Slope

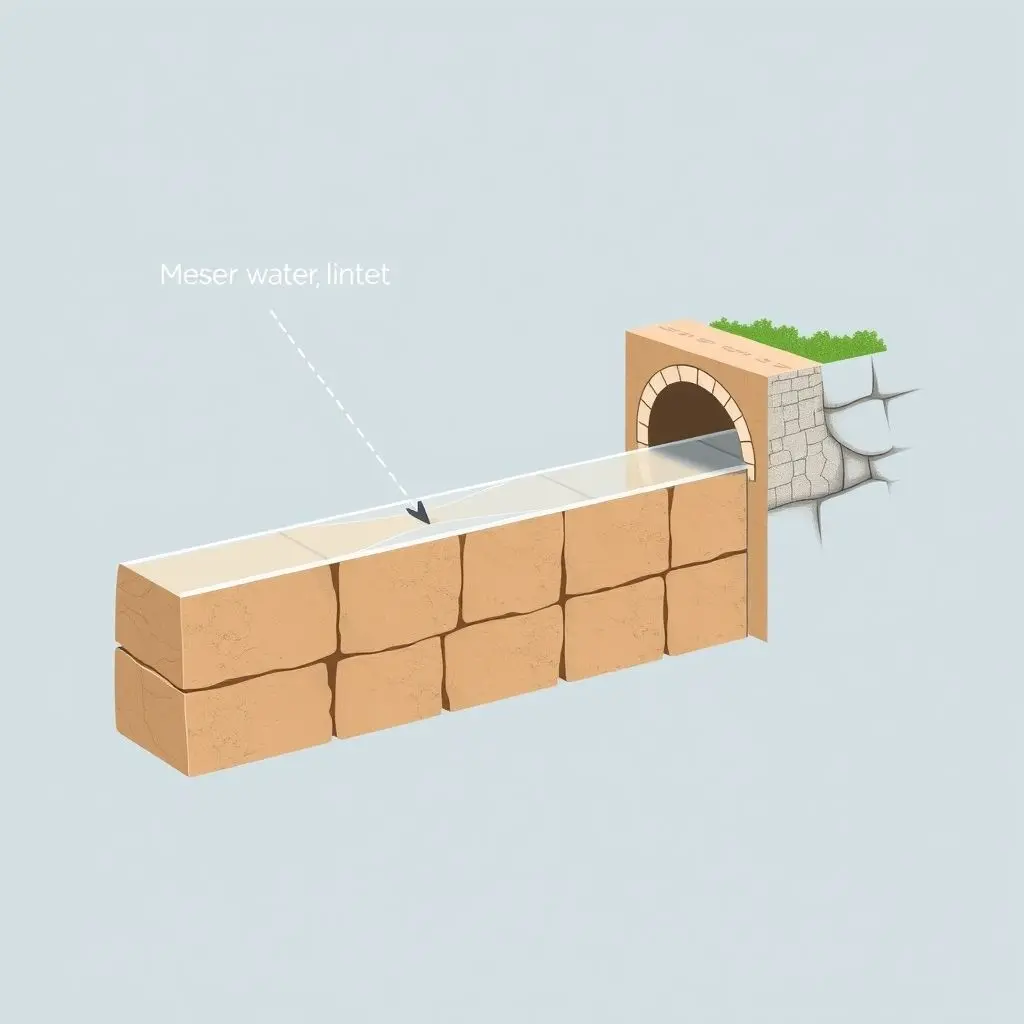

The genius of Roman aqueducts lay in maintaining a precise, shallow gradient over their entire length. This required incredibly accurate surveying techniques. Roman surveyors used tools like the groma (to establish right angles), the chorobates (a leveling instrument essentially a long wooden frame with a water channel), and the dioptra (similar to a theodolite). They had to plot routes that accounted for topography, ensuring a continuous, gentle downhill flow.

Construction Materials and Techniques

Romans were masters of materials, particularly concrete (opus caementicium), which allowed them to build strong, durable structures like the iconic arches. The water channels themselves (the specus) were often lined with waterproof plaster (opus signinum) to prevent leaks and keep the water clean. They built sections using cut stone, bricks, and concrete, adapting techniques to the local environment.

Crossing Obstacles: Bridges, Tunnels, and Siphons

Valleys and rivers were crossed using magnificent arched bridge structures (like the Pont du Gard). Hills and mountains were traversed through tunnels, often chiseled by hand from multiple access points, requiring precise alignment. For deeper valleys, Romans sometimes employed inverted siphons using lead pipes or sometimes stone-built pressure conduits, though arches were often preferred as lead was expensive and siphons were prone to bursting under pressure.

Maintaining the flow required constant vigilance. Access points were built along the route for cleaning and repairs, removing sediment and calcium buildup.

Lessons from History’s Original Tech Giants

These ancient wonders weren’t just built; they were *engineered*. They represent peak problem-solving with the available technology. The Egyptians mastered logistics, material handling on an immense scale, and incredible precision in stonework and astronomy (for orientation). The Romans excelled in surveying, hydraulics, material science (concrete!), and robust civil infrastructure.

Their solutions were often elegant in their simplicity, leveraging natural principles like gravity and the expansive properties of materials, combined with meticulous planning and organization. They remind us that innovation isn’t solely about complex gadgets; it’s about understanding fundamental forces and applying them creatively to overcome limitations.

These enduring structures serve as powerful reminders that determination, ingenuity, and a deep understanding of the physical world can lead to creations that last for millennia, shaping the course of civilization.

Frequently Asked Questions About Ancient Engineering

Q: Was this technology truly advanced, or just clever use of simple tools?

A: It was both. The tools themselves were relatively simple (levers, ramps, chisels, ropes), but the *application* of these tools, combined with advanced understanding of geometry, physics (leverage, gravity, fluid dynamics basics), surveying, and material properties, was incredibly sophisticated and constitutes advanced engineering for their time.

Q: Could modern builders replicate these structures using only ancient techniques?

A: Replicating them precisely using *only* the tools and methods available back then would be incredibly challenging, time-consuming, and require a massive labor force, likely exceeding modern safety standards and capabilities within a comparable timeframe. While the *principles* are understood, the practical execution at that scale is a different matter without modern power tools, machinery, and materials.

Q: How did they achieve such precision without modern instruments?

A: Ancient civilizations developed their own precise instruments and techniques based on astronomy, geometry, and observation. For leveling (aqueducts, pyramid bases), tools like the chorobates or simple water levels were used. For straight lines and right angles, ropes, plumb bobs, and tools like the groma were essential. Their mastery came from generations of accumulated knowledge, careful craftsmanship, and repeated practice.

Q: Were the workers slaves?

A: For the Egyptian pyramids, evidence suggests the workforce consisted primarily of skilled laborers and craftsmen, supplemented by temporary workers (possibly peasants during the Nile’s inundation season) who were housed, fed, and compensated. While slavery existed in ancient societies, large-scale state projects like the pyramids and aqueducts often relied on organized, paid, or conscripted labor forces with specific skills.