Ever heard whispers of a material so bizarre, so futuristic, it sounds straight out of a sci-fi movie? Imagine a metal that defies conventional physics, behaving more like glass than steel. This isn’t just a fantasy; it’s a real-world marvel known as Liquidmetal, or ‘amorphous metal,’ and it’s a material that Apple has held exclusive patents for years. Prepare to have your perception of what metal can do completely redefined.

While the name might conjure images of shapeshifting robots, Liquidmetal is far more incredible, and far more subtle, in its potential. Its unique atomic structure grants it a suite of properties that could fundamentally change the durability, aesthetics, and even performance of our beloved gadgets. From iPhones that never scratch to watches that bounce instead of breaking, the possibilities are genuinely mind-boggling.

Before we dive deep into the fascinating science and the tantalizing future Apple might be building, here’s a quick, mind-blowing primer on Liquidmetal:

Table of Contents

What Exactly is Liquidmetal? Unpacking Amorphous Alloys

At its core, Liquidmetal isn’t a single element but a family of alloys (mixtures of metals) characterized by their amorphous structure. To truly grasp why this is so revolutionary, let’s contrast it with the metals you encounter every day.

Crystalline vs. Amorphous: A Fundamental Difference

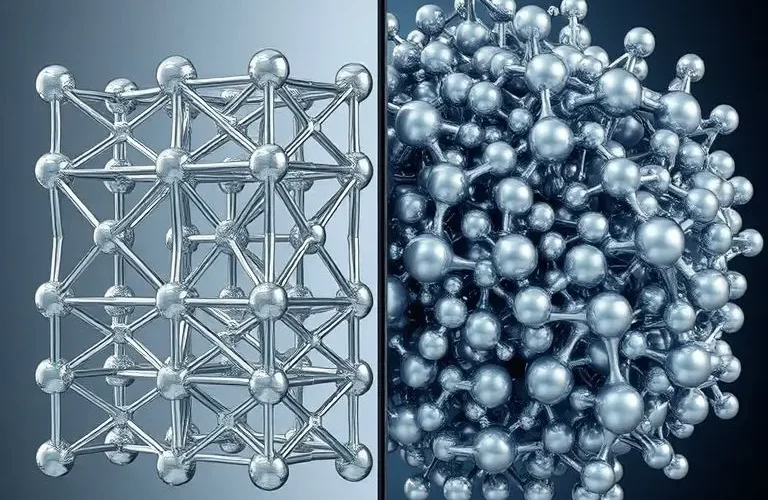

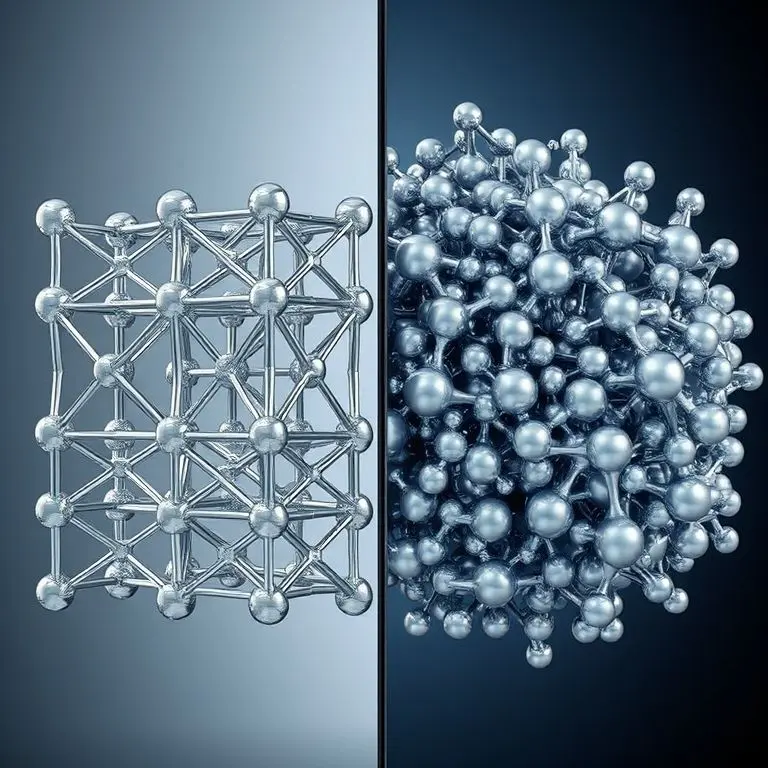

- Crystalline Metals: Most metals we use, like steel, aluminum, or copper, have a highly ordered, repetitive atomic arrangement. Think of a meticulously stacked brick wall; each atom sits in a specific, predictable lattice. This structure, while strong, creates ‘grain boundaries’ – weak points where dislocations can occur, leading to deformation or fracture under stress.

- Amorphous Metals (Metallic Glass): Liquidmetal defies this order. Its atoms are arranged randomly, much like those in glass or plastic. There’s no repeating pattern, no crystalline lattice, and critically, no grain boundaries. This ‘jumbled’ state is achieved by cooling the molten metal incredibly rapidly – so fast that atoms don’t have time to organize themselves into a crystalline structure before solidifying.

This structural anarchy is precisely what gives Liquidmetal its extraordinary properties, setting it apart as a true ‘supermaterial’ in the making.

The Superpowers of Metallic Glass: Why It’s a Game-Changer

Because of its unique atomic disarray, Liquidmetal boasts a combination of characteristics that are virtually unparalleled in conventional metals:

Unrivaled Strength and Hardness

Liquidmetal can be significantly stronger and harder than even high-grade steel. Without the weak points of grain boundaries, it can resist plastic deformation (permanent bending or denting) far more effectively. This means gadgets made from it would be incredibly resistant to everyday wear and tear, dings, and scratches.

Exceptional Elasticity and Resilience

Unlike regular metals that deform permanently beyond a certain point, Liquidmetal exhibits ‘superelasticity.’ It can absorb a tremendous amount of energy and return to its original shape without any deformation. Imagine a device that literally bounces back from drops, maintaining its pristine form. This property is often likened to the elastic behavior of rubber or plastic, but with the strength of metal.

Superior Corrosion Resistance

The absence of grain boundaries also makes Liquidmetal incredibly resistant to corrosion and oxidation. There are fewer sites for corrosive agents to attack, meaning devices would maintain their aesthetic appeal and structural integrity for much longer, even in harsh environments.

Lightweight Yet Robust

While its density can vary depending on the specific alloy, Liquidmetal can offer a fantastic strength-to-weight ratio. This allows for thinner, lighter, yet incredibly strong components, a holy grail for portable electronics.

Acoustic and Thermal Advantages

The amorphous structure can also offer benefits in acoustic dampening and thermal management. Its ability to absorb and dissipate energy could lead to better speaker enclosures, improved haptic feedback mechanisms, and more efficient heat sinks in devices.

Apple’s Liquidmetal Journey: From Exclusive Patent to Unrevealed Potential

Apple’s interest in Liquidmetal isn’t new. Back in 2010, the Cupertino giant secured an exclusive, perpetual worldwide license to use Liquidmetal Technologies’ amorphous metal alloys in its consumer electronic products. This was a massive move, giving Apple sole rights to integrate this cutting-edge material into its vast product ecosystem.

So, where is it? If it’s so amazing, why isn’t every iPhone draped in this indestructible alloy?

For years, the most prominent (and, let’s be honest, somewhat underwhelming) public application of Liquidmetal by Apple was in the SIM ejector tool included with certain iPhones. A small, seemingly insignificant component, it served as a quiet testament to the material’s precision molding capabilities, but hardly showcased its full potential.

The truth is, while Liquidmetal holds immense promise, its integration into mass-produced consumer electronics faces significant hurdles, primarily related to manufacturing scalability and cost. Producing large, intricate parts from amorphous metals requires extremely precise temperature control and rapid cooling rates, which are difficult and expensive to achieve at the enormous volumes Apple demands.

However, the patent isn’t just about what Apple has done; it’s about what it can do. By holding the exclusive license, Apple controls the destiny of Liquidmetal in consumer tech, preventing competitors from leveraging its advantages. This strategic move suggests a long-term vision, patiently waiting for manufacturing processes to mature or for a breakthrough that makes large-scale adoption feasible.

The Vision: What Could Apple Build with Liquidmetal?

The potential applications of Liquidmetal in Apple’s product line are nothing short of transformative. Imagine a world where:

- Indestructible iPhones and Apple Watches: The dream of a scratch-proof, ding-proof, and significantly more drop-resistant device could become a reality. Imagine an iPhone casing that feels like glass but possesses the resilience of steel, shrugging off impacts that would shatter current devices.

- Enhanced Haptic Feedback and Buttons: Liquidmetal’s elasticity could allow for incredibly precise, durable, and responsive buttons or haptic engines, offering a superior tactile experience without mechanical wear.

- Advanced Device Enclosures: Thinner, lighter, yet stronger chassis for MacBooks, iPads, or even future AR/VR headsets. The material’s moldability could also enable more intricate and ergonomic designs.

- Improved Audio Components: Better speaker grilles or internal acoustic chambers that could enhance sound quality by reducing unwanted vibrations.

- Efficient Thermal Management: Parts designed to dissipate heat more effectively, allowing for more powerful processors in smaller form factors without overheating concerns.

- New Material Textures and Finishes: The ability to create unique, non-metallic yet metallic-feeling surfaces that resist fingerprints and maintain a premium aesthetic over time.

This material isn’t just about incremental improvements; it represents a paradigm shift in device durability and design, unlocking possibilities that traditional metals simply cannot offer.

Challenges and the Road Ahead

Despite its incredible promise, Liquidmetal isn’t a silver bullet. The primary hurdles remain:

- Manufacturing Complexity: As mentioned, achieving the rapid cooling rates necessary for large, complex amorphous parts is challenging. It requires specialized equipment and precise control, leading to higher production costs and potentially slower manufacturing times.

- Material Limitations: While incredibly strong and elastic, some amorphous metals can be less ductile (able to be stretched into wire) than their crystalline counterparts, limiting their application in certain scenarios requiring significant bending or drawing.

- Cost: Currently, the specialized processing makes Liquidmetal significantly more expensive than conventional alloys, making mass adoption in price-sensitive consumer electronics difficult.

However, Apple’s continued investment and licensing suggest that these challenges are seen as surmountable. As manufacturing techniques advance and economies of scale become more attainable, the widespread integration of Liquidmetal into our daily tech might be closer than we think.

FAQs About Liquidmetal and Apple

Is Liquidmetal currently in any Apple products?

Beyond the occasional use in SIM ejector tools, there’s no widespread, confirmed integration of Liquidmetal in major components of current Apple products like iPhones, Apple Watches, or MacBooks. Apple holds patents and licenses, indicating a long-term strategy rather than immediate deployment.

Why isn’t Apple using Liquidmetal more widely?

The primary reasons are manufacturing challenges related to scalability and cost. Producing large, complex parts from amorphous metals is technically difficult and expensive at the volumes Apple requires for its consumer electronics line.

What are the main advantages of Liquidmetal?

Liquidmetal boasts exceptional strength, elasticity (it can bounce back from impacts), superior corrosion resistance, and a high strength-to-weight ratio. These properties make it incredibly durable and resistant to scratches and dents.

Is Liquidmetal safe?

Yes, Liquidmetal alloys are generally considered safe. They are non-toxic and stable, similar to other metallic alloys used in consumer products. The material has also been explored for medical device applications, further indicating its safety.

When can we expect more Liquidmetal tech from Apple?

There’s no public roadmap for Liquidmetal integration into Apple’s mainstream products. Its deployment will likely depend on advancements in manufacturing techniques that make it cost-effective and scalable for mass production. It remains a fascinating ‘hidden’ technology in Apple’s arsenal.

A Glimpse into the Future of Tech Durability

Liquidmetal is more than just a quirky material; it represents a frontier in materials science, holding the key to a future where our devices are not just smart, but also virtually indestructible. Apple’s long-standing exclusive license is a powerful statement about its belief in this material’s potential, quietly stewarding its development behind the scenes.

While the full story of Liquidmetal’s impact on our daily tech is still unfolding, the promise of an iPhone that never scratches or an Apple Watch that simply bounces away a fall is a future worth anticipating. It’s a testament to the fact that some of the most profound innovations often lie hidden in plain sight, waiting for their moment to redefine what’s possible.