Ever tried to cook an egg, only to watch it stubbornly cling to the pan, leaving behind a frustrating, stuck-on mess? Then you know the struggle. But what if that same egg just… glided off, leaving your pan sparkling clean with barely a wipe? That’s not magic, it’s the ingenious work of non-stick technology, a marvel of material science we often take for granted. At its heart lies a truly remarkable substance: Polytetrafluoroethylene – thankfully, most of us just call it PTFE, or by its famous brand name, Teflon.

If you’re keen on seeing this frictionless phenomenon in action and getting a quick, engaging peek into its core secrets, take a moment to watch our recent YouTube Shorts video below. It’s a snappy visual breakdown that perfectly complements what we’re about to dive into!

Right? It’s pretty slick! But there’s a whole universe of surprising chemistry behind that effortless slide, a tale of incredibly strong bonds, accidental discovery, and a material that has revolutionized not just our kitchens, but countless industries worldwide.

Table of Contents

The Unsung Hero: What Exactly IS PTFE?

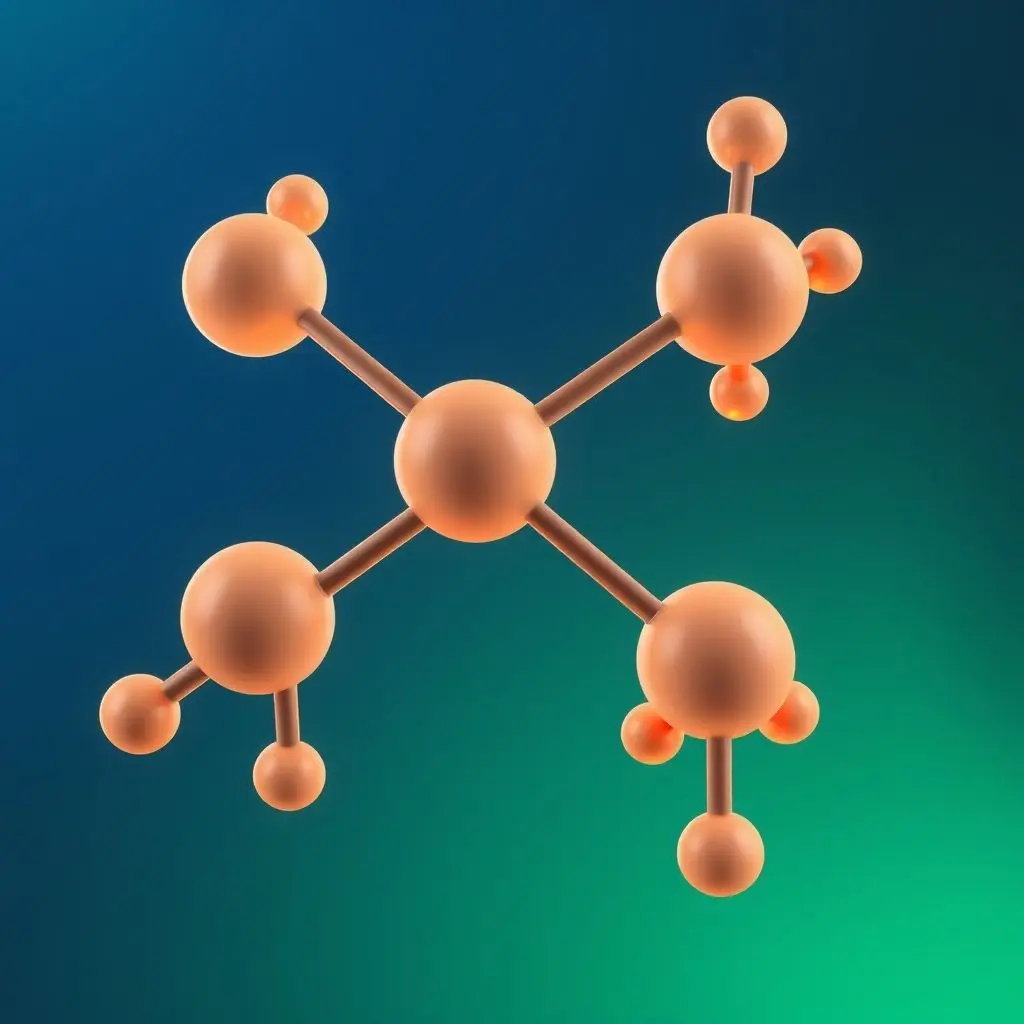

So, what precisely is this wonder material, PTFE? At its core, Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene. Sounds like a mouthful, doesn’t it? Think of it as a long, spaghetti-like chain of carbon atoms, each one completely saturated with fluorine atoms. This might seem simple, but it’s the peculiar relationship between these carbon and fluorine atoms that gives Teflon its superpowers.

The Molecular Marvel: Carbon-Fluorine Bonds

The secret sauce lies in the carbon-fluorine (C-F) bond. This particular chemical bond is one of the strongest known in organic chemistry. Why does that matter? Well, strength here translates directly into unparalleled stability and inertness. Because these bonds are so incredibly robust, they are reluctant to react with other substances. Furthermore, the fluorine atoms are quite large and create a kind of ‘shield’ around the carbon backbone, making the entire polymer chain both chemically non-reactive and incredibly stable even under challenging conditions.

The Magic Touch: How Non-Stick Actually Works

Imagine a surface so smooth, so stable, that anything touching it simply can’t get a grip. That’s essentially what happens with Teflon. The tightly packed, stable fluorine atoms form an incredibly uniform, low-energy surface. To understand this, think about water on a waxed car versus water on raw wood. On wax, water beads up and rolls off – that’s low surface energy. On wood, it soaks in – high surface energy.

Low Surface Energy: The Key to Repulsion

In the world of chemistry, everything tries to minimize its energy. If a liquid (like food molecules or oil) comes into contact with a solid surface, it will try to maximize its contact area if the surface has high energy, leading to ‘wetting’ or sticking. But on a Teflon surface, the van der Waals forces – the weak intermolecular attractions that cause things to stick – are incredibly feeble. The strong C-F bonds create an electron cloud that is very symmetrical and non-polar, meaning there are no ‘sticky’ charges or regions for other molecules to grab onto. Food molecules, therefore, find it energetically unfavorable to form strong bonds with the PTFE surface. They literally ‘bounce’ off, resulting in that satisfying non-stick slide, making cooking and cleanup a breeze.

A Fortuitous Fumble: The Accidental Discovery of Teflon

Like many truly revolutionary inventions, Teflon wasn’t intentionally designed for non-stick cookware. Its discovery in 1938 by Dr. Roy J. Plunkett at DuPont was a magnificent accident. Plunkett was working on new refrigerants, specifically experimenting with tetrafluoroethylene gas (TFE) in cylinders. One fateful morning, he opened a cylinder that was supposed to contain TFE gas, but nothing came out. Puzzled, he cut open the cylinder, expecting to find it empty. Instead, he found a slippery, white, waxy powder coating the inside. The TFE gas had spontaneously polymerized under pressure, forming Polytetrafluoroethylene – or PTFE.

This serendipitous discovery led to a material with properties so unique – extreme heat resistance, chemical inertness, and incredible slipperiness – that DuPont patented it in 1941 and trademarked it as Teflon in 1945. It took a while before it found its way into kitchens, but once it did, cooking was never the same.

Beyond the Pan: Where Else Does Teflon Shine?

While Teflon’s household fame comes from cookware, its incredible properties have made it indispensable across a vast array of industries. Its low friction, chemical inertness, and heat resistance make it ideal for much more than just frying eggs. Consider these diverse applications:

- Aerospace: Used in critical components for spacecraft and aircraft due to its resistance to extreme temperatures, harsh chemicals, and corrosive environments.

- Medical Devices: Its biocompatibility (meaning it doesn’t react negatively with biological tissue) makes it perfect for a range of applications, including implants, catheters, and surgical instruments.

- Industrial Applications: From chemical pipelines to bearing linings, seals, and gaskets, PTFE reduces friction, prevents corrosion, and provides reliable performance in demanding industrial settings.

- Textiles: As a coating, it makes fabrics highly stain-resistant and waterproof (think advanced outdoor gear and protective clothing).

- Electrical Insulation: Its excellent dielectric properties make it a superior insulator for wires, cables, and electronic components, especially in high-performance applications.

Addressing the Concerns: Safety, Scratches, and Smart Use

Despite its widespread utility and revolutionary impact, Teflon has faced scrutiny, particularly regarding safety concerns. It’s crucial to separate fact from sensationalism here.

The PFOA/PFOS Question: Dispelling Myths

Historically, an industrial chemical called PFOA (perfluorooctanoic acid) was used in the manufacturing process of some Teflon products. Concerns arose about its potential health effects and persistence in the environment. However, it’s vital to understand that PFOA was phased out of non-stick cookware manufacturing by 2013 by major manufacturers, including DuPont, due to a voluntary agreement with the U.S. Environmental Protection Agency (EPA). Modern Teflon coatings are now produced without PFOA (and related legacy chemicals like PFOS).

When used as intended – typically below 500°F (260°C), the temperatures common for stovetop cooking – PTFE coatings are stable and safe. At extremely high temperatures (above 570°F or 300°C), which are rarely reached in normal kitchen cooking, the coating can begin to break down, potentially releasing fumes. While these fumes are generally harmless to humans, they can cause temporary flu-like symptoms in rare cases, often referred to as ‘Teflon flu.’ It’s always a good practice to ensure adequate ventilation in your kitchen, especially when cooking at higher heats.

Regarding scratched pans: small scratches generally don’t pose a significant health risk. However, to maintain optimal non-stick performance and prolong the life of your cookware, it’s best to use silicone, wooden, or plastic utensils and avoid abrasive cleaners. If a pan is heavily scratched or peeling, it’s advisable to replace it, not because of health risks from ingesting flakes (which are inert), but because its non-stick properties will be compromised.

Disclaimer: Always follow manufacturer guidelines for care and use of your non-stick cookware to ensure safety and longevity.

The Enduring Legacy of Non-Stick Technology

From a surprising lab discovery to a household staple and an industrial workhorse, the journey of Teflon and non-stick technology is a testament to the power of scientific innovation – even when it happens by pure chance. The seemingly simple act of an egg sliding effortlessly off a pan is, in fact, a fascinating interplay of atomic bonds, molecular structures, and surface energy, making our daily lives just a little bit easier.

So, the next time you marvel at that perfect flip in your non-stick pan, remember the intricate, yet elegant, science of Polytetrafluoroethylene. It’s truly a marvel of modern chemistry that continues to redefine convenience in the kitchen and beyond.

Frequently Asked Questions (FAQs) About Non-Stick Cookware

- What exactly is Teflon?

- Teflon is the well-known brand name for a synthetic fluoropolymer called Polytetrafluoroethylene (PTFE).

- Is Teflon safe to use?

- Yes, modern Teflon coatings are considered safe for normal cooking. The concerns about PFOA are largely outdated, as manufacturers phased out its use in non-stick cookware production many years ago.

- How does non-stick work at a molecular level?

- It works primarily due to the incredibly strong and stable carbon-fluorine bonds in PTFE. These bonds create a highly non-reactive surface with very low surface energy, which prevents food molecules from forming strong adhesions and causes them to slide off instead.

- What should I do if my non-stick pan gets scratched?

- While small, isolated scratches are generally harmless, it’s best to replace pans with significant or widespread damage. This helps maintain optimal non-stick performance and prevents further flaking. Always use non-abrasive utensils to prevent scratches.

- Can I use non-stick pans on high heat?

- It’s generally recommended to avoid extremely high temperatures (above 500°F or 260°C) as this can potentially degrade the coating over time. Medium heat is usually sufficient for most cooking on non-stick surfaces and helps prolong the pan’s life.