We live in an age where technology evolves at lightning speed. Your smartphone from last year feels ancient, and innovation is measured in months, sometimes weeks. We marvel at sleek designs, powerful processors, and connectivity that would have seemed like science fiction just decades ago. But what if I told you about a piece of ‘tech’ built in the 1930s, a time of economic despair, that was so visionary, so groundbreaking, it remains a vital, functioning powerhouse nearly a century later?

Welcome to the world of the Hoover Dam. This isn’t just a wall of concrete; it was a leap into the future, an industrial-scale marvel that tackled challenges never before attempted and succeeded with breathtaking audacity. It’s a powerful reminder that true ingenuity, built right, can indeed stand the test of time.

Table of Contents

A Vision Forged in Stone and Steel

At the dawn of the 20th century, the Colorado River was a force of nature, untamed and unpredictable. Its seasonal floods devastated downstream communities and valuable farmland, while its potential as a source of water and power for the arid Southwest remained largely untapped. The idea of harnessing this wild river was ambitious, but the sheer scale and engineering hurdles were immense.

The project, initially known as the Boulder Dam, was conceived not just as a flood control measure but as a multi-purpose solution providing irrigation water, municipal water supply, and, crucially, hydroelectric power. Undertaking such a massive public works project during the Great Depression (1929-1941) also served a critical purpose: creating desperately needed jobs.

Mega-Engineering Challenges and Pioneering Solutions

Building the world’s highest dam in the remote, rugged Black Canyon required overcoming challenges that simply had no existing blueprints. The engineers and workers of the 1930s had to invent solutions on the fly, pushing the boundaries of materials science, civil engineering, and project management.

Diverting the Mighty Colorado

First, the river itself had to be rerouted. This was achieved by drilling four massive tunnels, each 56 feet in diameter and totaling nearly 16,000 feet in length, through the canyon walls. These tunnels, lined with concrete, were capable of handling the full flow of the Colorado River during construction. Once the dam was complete, two of these tunnels were plugged, while the other two were partially used for the spillways.

Concrete: More Than Just a Mix

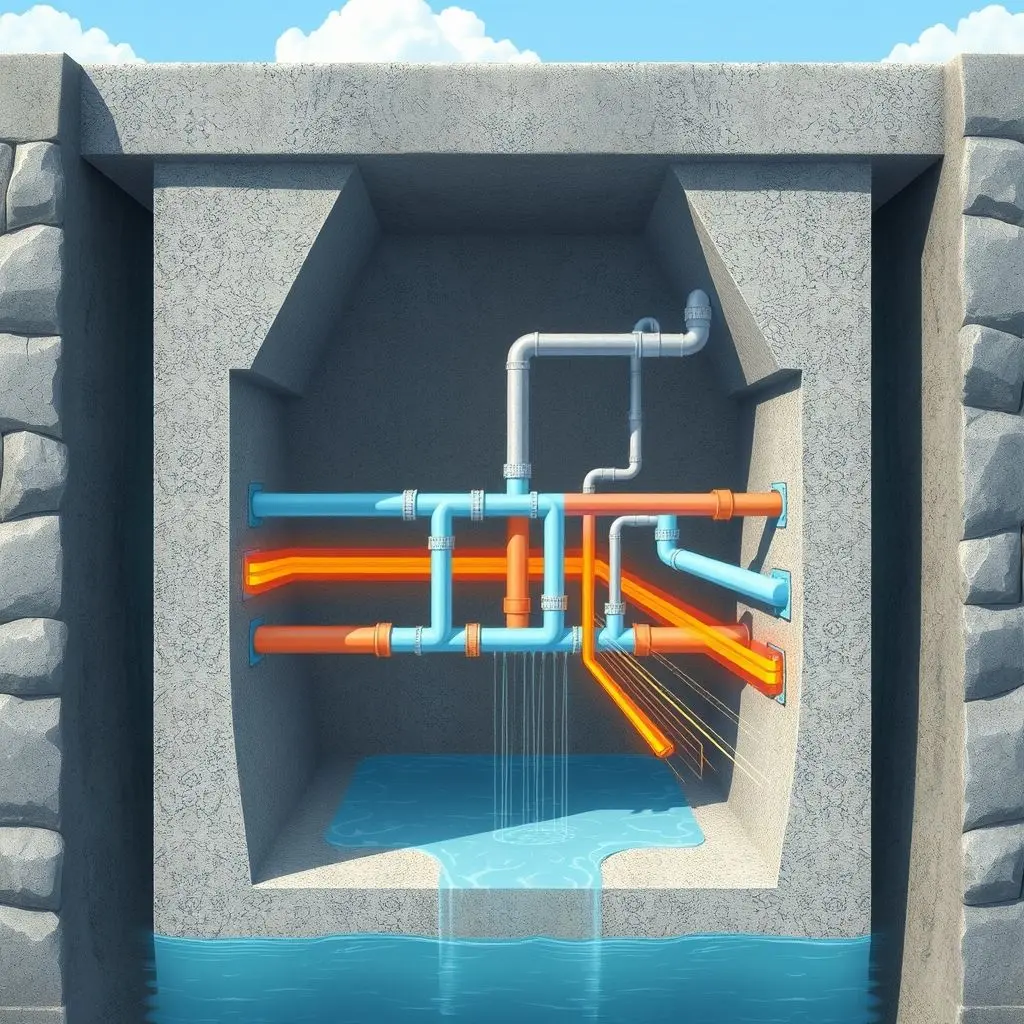

The sheer volume of concrete required was staggering – enough to build a road from San Francisco to New York City. Pouring such a massive monolithic block (the dam is 660 feet thick at its base) presented a unique problem: concrete generates heat as it cures. If left unchecked, this heat would cause uneven cooling and cracking, compromising the dam’s structural integrity for centuries.

The innovative solution? Embedding a network of over 590 miles of 1-inch steel pipe within the concrete blocks. Chilled river water, and later refrigerated water, was circulated through these pipes, artificially cooling the concrete as it cured. This wasn’t just pouring concrete; it was a carefully orchestrated thermal management process on an unprecedented scale.

Materials Transport and Handling

Moving millions of cubic yards of earth, rock, and concrete in the narrow canyon was another logistical nightmare. The solution involved constructing a complex system of high-speed cableways strung across the canyon, capable of transporting materials weighing up to 20 tons. Specialized concrete buckets and innovative handling techniques were developed to deliver the mix precisely where it was needed, block by block.

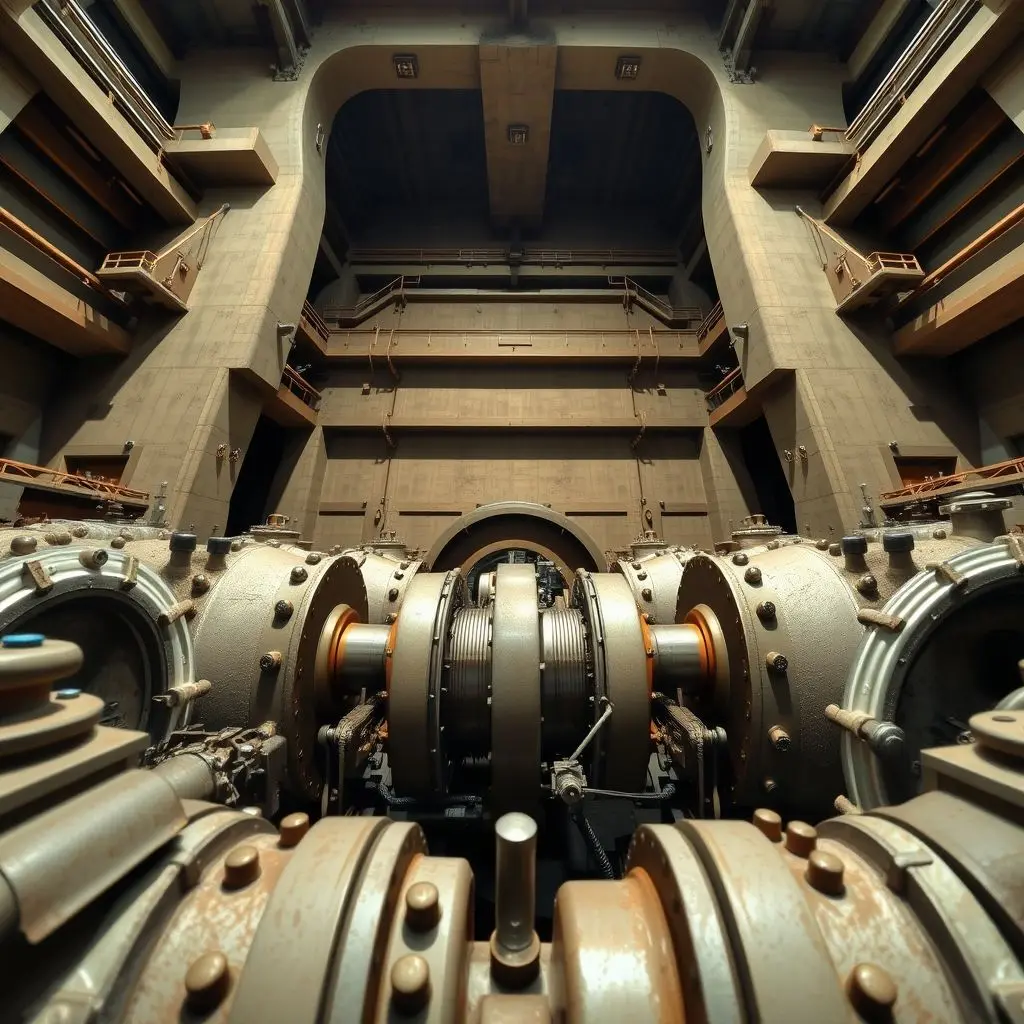

Building the Powerhouse

Integrated into the base of the dam structure is the U-shaped powerhouse. Constructing this facility, which would house colossal turbines and generators, required further engineering feats. The intake towers, visible upstream, control the flow of water through immense penstock pipes (up to 30 feet in diameter) that feed the turbines below. These pipes were fabricated and transported in sections and assembled on-site under incredibly challenging conditions.

Harnessing the River’s Force: The Power Generation

The true ‘tech’ heart of the Hoover Dam lies within its powerhouse. The original installation included 17 Francis-type turbines connected to generators. These machines were engineering marvels of their time, designed to convert the kinetic energy of falling water from Lake Mead into electrical energy.

Water rushing through the penstocks spins the massive turbines, which in turn spin the rotors of the generators. These generators produce alternating current (AC) electricity, which is then stepped up in voltage by transformers before being transmitted via high-voltage lines across vast distances.

Today, the Hoover Dam Powerplant has a total of 17 main turbines (9 on the Arizona side, 8 on the Nevada side) and two small pelton-type turbines for local needs. With a generating capacity of over 2,000 megawatts, it still provides clean, renewable power to millions of people in Nevada, Arizona, and California.

Thinking about the scale and innovation required nearly 100 years ago is mind-boggling, isn’t it? To get a quick glimpse of this engineering marvel, check out our YouTube Short:

Still Standing, Still Serving

Beyond its initial construction, the Hoover Dam was designed for longevity. The concrete curing method, the robust design, and ongoing maintenance have ensured its continued operation. Lake Mead, the reservoir created by the dam, is the largest man-made reservoir in the United States by volume (when full), providing crucial water storage for the region.

The dam’s primary functions remain critical: flood control for the lower Colorado River basin, water storage and delivery to arid regions, and hydroelectric power generation. While the river flow and water levels in Lake Mead fluctuate, the infrastructure built in the 1930s continues to perform its vital roles.

A Monument to Human Ingenuity

The Hoover Dam project was completed in just five years, ahead of schedule and under budget, a remarkable achievement given the challenges. It came at a significant human cost, with tragic accidents occurring during the dangerous construction process, highlighting the immense bravery and sacrifice of the workers.

Yet, the dam stands today not just as a physical structure, but as a symbol of human determination, technological prowess, and the ability to achieve the seemingly impossible. It’s a powerful counterpoint to our modern culture of planned obsolescence, a piece of ‘mega-tech’ from the 1930s that was truly built to last.

Frequently Asked Questions (FAQs)

How old is the Hoover Dam?

Construction on the Hoover Dam began in 1931 and was completed in 1936. This means it is currently nearing its 90th anniversary, a true testament to its durability.

Is the Hoover Dam still operational?

Absolutely! The Hoover Dam is fully operational and continues to serve its original purposes of flood control, water management, and hydroelectric power generation for parts of Arizona, Nevada, and California.

How much power does the Hoover Dam generate?

The Hoover Dam Powerplant has a generating capacity of over 2,000 megawatts. Its actual output varies depending on the water level of Lake Mead and regional power demand.

What makes the Hoover Dam’s construction so impressive?

Its impressive construction stems from overcoming unprecedented challenges with innovative solutions for the time, including diverting a major river, managing the heat of curing concrete on a massive scale, transporting materials across a rugged canyon, and installing colossal power generation equipment, all during an era with less advanced technology than today.

How long did it take to build the Hoover Dam?

Construction was completed in just five years, from 1931 to 1936.

Looking Back While Moving Forward

In a world captivated by the next big tech release, pausing to appreciate engineering feats like the Hoover Dam offers valuable perspective. It demonstrates that foundational, robust technology, conceived with vision and executed with skill, can have an impact that spans generations. The lessons learned from this colossal project continue to influence large-scale engineering and construction today. It stands as a monument to what we can achieve when we dare to dream big and build durably.