Imagine holding a substance that feels like it’s barely there, almost defying gravity. A material so ethereal it’s been nicknamed ‘frozen smoke’ or even ‘solid air’. Yet, this seemingly insubstantial stuff is, in fact, a solid – and not just any solid, but quite possibly the lightest one known to exist on our planet.

Welcome to the fascinating world of Aerogel.

Before we dive deep, take a quick peek at this mind-bending material in action. It gives you a sense of just how unique Aerogel truly is:

Yes, as that glimpse showed, we’re talking about a substance that can be up to 99.8% air by volume. Think about that: a solid composed almost entirely of *nothingness*! This extreme porosity is the secret to many of Aerogel’s astonishing properties.

Table of Contents

So, What Exactly Defines Aerogel?

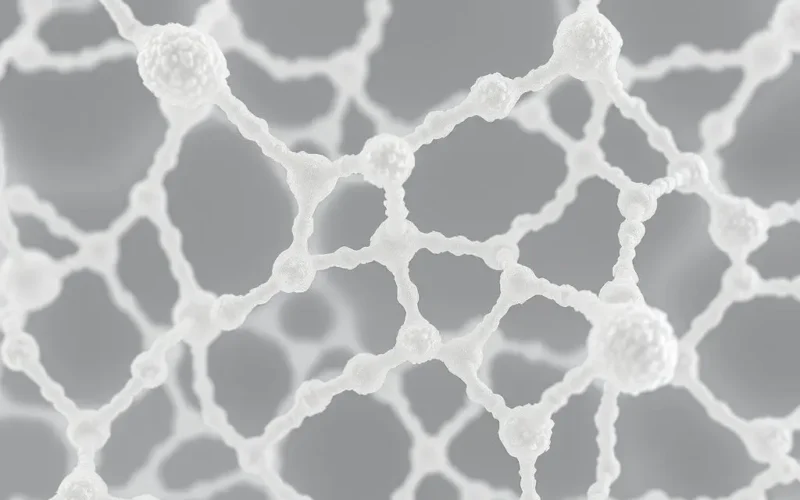

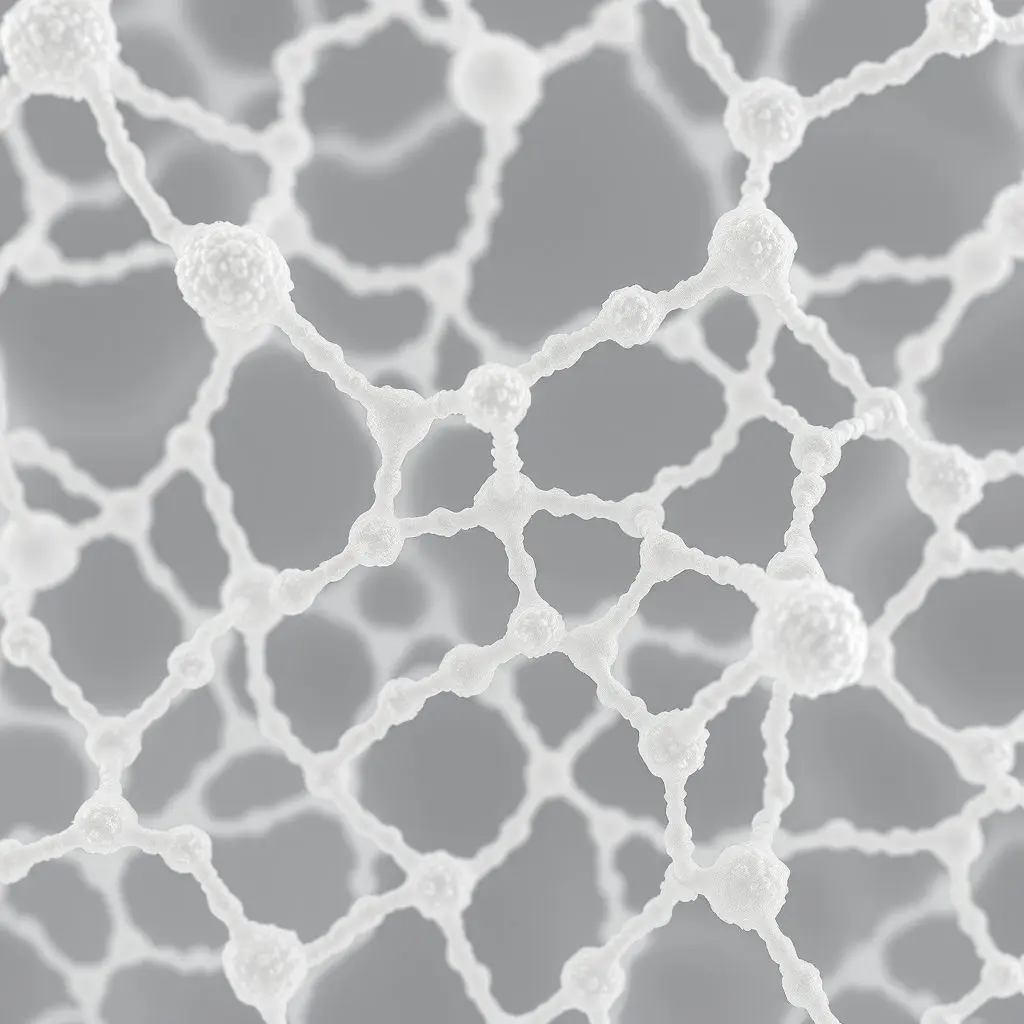

At its core, Aerogel is a synthetic porous ultralight material derived from a gel, in which the liquid component has been replaced with gas. The process sounds simple enough, but the magic lies in *how* that liquid is removed.

Think of a standard gel, like gelatin or jelly. It’s a solid network (often proteins or polymers) trapping a liquid (usually water). If you just let a typical gel dry out in the air, the surface tension of the evaporating liquid would cause the delicate solid structure to collapse and shrink into a dense, hard solid. That’s not Aerogel.

The key to creating Aerogel is a technique called supercritical drying. In this process, the liquid within the gel is brought to a supercritical state – a point where it’s neither a distinct liquid nor a gas. Then, by carefully depressurizing and raising the temperature, the supercritical fluid is transitioned directly into a gas phase *without* ever crossing the liquid-gas boundary where surface tension forces would wreak havoc. This preserves the gel’s original, expansive solid network structure, leaving behind a material that is mostly empty space (air).

The most common type of Aerogel is silica aerogel, made from silica gel. But aerogels can also be made from other materials like carbon, polymers, metal oxides, and even cellulose (derived from plants).

‘Frozen Smoke’: Why the Haunting Nickname?

The nickname ‘frozen smoke’ is perhaps the most evocative description of Aerogel’s appearance. Because its solid structure is so sparse and the pores are so tiny (often in the nanometer range), light scatters through it in a way that makes it appear semi-translucent and slightly hazy, much like smoke. The term ‘frozen’ implies that this wispy appearance is held in a solid form.

While it looks delicate and smoky, it’s surprisingly rigid due to the continuous solid network. However, its rigidity doesn’t translate to high tensile strength; many types, especially silica aerogel, can be brittle and easily fractured or crushed.

The Superpowers of This ‘Solid Air’

Despite being mostly air, Aerogel boasts a suite of properties that make it incredibly useful and unique in material science:

- Extreme Lightness: This is its defining characteristic. With densities ranging from 0.0011 to about 0.5 g/cm³, some silica aerogels are only slightly denser than air (density of air is about 0.001225 g/cm³ at sea level). A piece of Aerogel large enough to fill a small car would weigh only a few pounds.

- Incredible Thermal Insulation: Because heat is primarily transferred through conduction, convection, and radiation, trapping air in extremely small pockets effectively minimizes all three. The solid structure is minimal, reducing conduction. The tiny pore size prevents air convection currents from forming. And the material itself can be chosen to minimize radiation transfer. This makes Aerogel one of the best thermal insulators known, far superior to traditional materials like fiberglass or foam. A thin layer can provide significant thermal shielding.

- Excellent Sound Insulation: The porous structure also makes it effective at damping sound waves, particularly at higher frequencies.

- Shock Absorption: The open, compressible network can absorb significant impact energy.

- Large Surface Area: The vast network of pores gives Aerogel an enormous internal surface area for its mass, making it useful for applications like catalysts or filters.

Where This Lightest Solid Makes a Heavy Impact

Given its extraordinary properties, Aerogel has found its way into various high-tech and niche applications:

- Space Exploration: Perhaps the most famous use is by NASA. Aerogel was used on the Stardust mission to capture cosmic dust particles. Its lightness and the fact that the particles would embed in the porous structure without vaporizing (due to low density and excellent insulation) made it the perfect ‘catcher’. It’s also used for insulating sensitive equipment and potentially in future spacesuits.

- High-Performance Insulation: Due to its superior thermal performance, Aerogel is used in challenging insulation applications where space is limited or extreme temperatures are involved, such as industrial pipelines, refrigeration units, and sometimes integrated into building materials or high-tech apparel.

- Particle Physics: In detectors like Cherenkov counters, Aerogel’s unique refractive index properties are used to detect high-energy particles.

- Potential Future Uses: Research is ongoing into using Aerogel for water purification (adsorbing pollutants), catalysts, chemical storage, drug delivery, and even flexible versions for textiles and construction.

Challenges and the Road Ahead

Despite its remarkable capabilities, Aerogel isn’t everywhere yet. Traditional silica aerogel manufacturing, particularly the supercritical drying step, is relatively complex and expensive compared to conventional materials. It can also be brittle and tends to shed dust, which can be irritating (silica dust isn’t great for lungs). Newer types, like polymer or carbon aerogels, offer more flexibility and strength but come with their own production challenges.

Scientists and engineers are continuously working to overcome these hurdles, developing simpler manufacturing processes, exploring new base materials, and creating composite Aerogel materials that are less brittle and easier to handle. As production becomes more efficient and costs decrease, we might see Aerogel becoming more common in everyday applications, revolutionizing everything from home insulation to performance clothing.

Frequently Asked Questions About Aerogel

- Is Aerogel safe to touch? Generally, silica aerogel is safe to touch, but it can be brittle and shed fine dust particles which can dry out skin and mucous membranes. It’s best to handle it carefully, perhaps with gloves. Other types of aerogels may have different handling precautions.

- How is Aerogel so light? It’s light because it’s primarily made of air – up to 99.8% by volume. The solid structure is a sparse network with very little mass compared to the volume it occupies.

- Is Aerogel strong? Aerogel has surprising compressive strength for its weight and can support thousands of times its own mass. However, it is typically brittle and can easily break if bent or subjected to shear forces, especially silica aerogel.

- Can I buy Aerogel? Yes, small samples are available online for educational purposes or curiosity. Sheets and granules for specific industrial or research applications are also available, though often at a high cost.

- What’s the difference between silica and carbon aerogel? Silica aerogel is made from silicon dioxide and is known for its exceptional thermal insulation. Carbon aerogel is made from carbon and is known for its electrical conductivity, making it useful in capacitors, electrodes, and fuel cells, while still offering good insulation.

A Material That Redefines ‘Solid’

Aerogel stands as a testament to the incredible possibilities within material science. By manipulating matter at the nanoscale, we can create substances that defy our everyday intuition about weight, structure, and insulation. This ‘frozen smoke’, the lightest solid on Earth, is not just a scientific curiosity; it’s a powerful tool pushing the boundaries in space exploration, energy efficiency, and potentially countless future technologies. It makes you wonder what other seemingly impossible materials are waiting to be discovered or engineered.